Case studies

Resourcing case study Sourcing IQ

Challenge

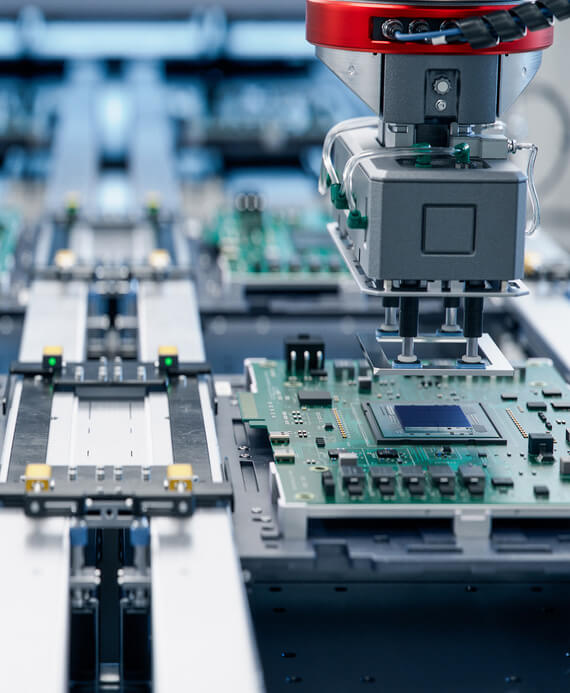

In manufacturing, when the core of your business – your supply chain and the components that make up your product – are irregular, it can have detrimental impacts on the bottom line. If focus is lost on sourcing and supply chain, internal inefficiencies, long lead times, total costs and product quality can all suffer.

That’s why our alternative energy client approached us. They wanted to overhaul their supply chain and sourcing approach and get pricing back in line with market values.

Strategy

Looking for a solution to improve overall business performance, we began at the source. We developed a “should-cost” model after engaging our global network of suppliers to identify suitable partners for the business.

From there, we assessed the global market and negotiated costs and a master supply agreement to secure favorable terms and conditions. This holistic approach allowed our client to reduce inventory and customer lead- times, reallocate internal resources, and secure total cost reductions that improved EBITDA performance.

Results

Our client saw significant savings and improvements in their business, including:

- $850,000 in annual cost savings, a reduction of 26%

- An annual rebate of $65k as a result of our negotiations

- Freeing up an additional $365k in working capital

- A lead time reduction of 33%

Case Studies

Read more Read more

Risk Assessment

Case Study

Training

Case Study

Reach out today for a consultation

Looking to improve your supply chain strategy and create efficiencies and savings? Upskill your team? Or see where you could be saving more?